Polyethylene PE1000 Sheet - UHMWPE Hnav-Resistant

Cov ntsiab lus

Polythylene PE 1000 daim ntawv feem ntau hu ua ultra-high-molecular-yuag, UHMW, lossis UHMWPE, yog ib qho ntawm peb cov khoom siv hluav taws xob nrov tshaj plaws.Nws muab kev tiv thaiv zoo heev rau kev puas tsuaj, tshuaj lom neeg, cuam tshuam thiab hnav, thiab muaj kev sib txhuam qis heev ntawm kev sib txhuam.UHMW kuj tsis muaj tshuaj lom, tsis muaj ntxhiab, thiab muaj kev tiv thaiv zoo rau feem ntau.

UHMW yas ntawv feem ntau machined rau hauv hnav strips, saw guides thiab hloov qhov chaw thiab yog ib tug nrov engineering yas nyob rau hauv cov zaub mov ua thiab bottling ua hauj lwm.Cov qib tshwj xeeb ntawm PE1000 kuj tseem siv rau hauv cov khoom siv los tuav cov ntawv thov rau kab chutes, hoppers thiab cov tsheb thauj khoom pov tseg, pab txhim kho cov khoom ntws thiab tiv thaiv kev tiv thaiv ratholing thiab arching.

Parameter

| Tsis muaj. | Yam khoom | Chav tsev | Test Standard | Kev tshwm sim |

| 1 | Qhov ntom | g/cm3 | GB/T1033-1966 | 0.91-0.96 Nws |

| 2 | Pwm shrinkage% | TIAB SA 6474 | 1.0-1.5 hli | |

| 3 | Elongation thaum so | % | GB/T1040-1992 | 238 |

| 4 | Tensile zog | Mpa | GB/T1040-1992 | 45.3 ib |

| 5 | Pob indentation hardness test 30g | Mpa | TIAB SA 2039-1 | 38 |

| 6 | Rockwell hardness | R | ISO 868 | 57 |

| 7 | Khoov zog | Mpa | GB / T9341-2000 | 23 |

| 8 | Compression zog | Mpa | GB/T1041-1992 | 24 |

| 9 | Static softening temp. | ENISO 3146 | 132 | |

| 10 | Tshwj xeeb kub | KJ (Kg.K) | 2.05 Nws | |

| 11 | Kev cuam tshuam lub zog | KJ/M3 | D-256 | 100-160 |

| 12 | Thaum tshav kub kub conductivity | % (m / m) | ISO 11358 | 0.16-0.14 dr hab |

| 13 | Sliding zog thiab kev sib txhuam coefficient | Plastic/STEEL (WET) | 0.19 ib | |

| 14 | Sliding zog thiab kev sib txhuam coefficient | Plastic/STEEL (DRY) | 0.14 ib | |

| 15 | Ntug hardness D | 64 |

Nta

1. Txhim kho hnav tsis kam.Ib qho ntawm cov khoom zoo tshaj plaws ntawm UHMW polyethylene yog nws cov kev ua haujlwm siab heev, uas yog qhov tseem ceeb hauv ntau daim ntawv thov engineering.Ntawm tag nrho cov yas, nws hnav tsis kam yog qhov zoo tshaj plaws, thiab txawm tias qhov hnav tsis tu ncua ntawm ntau cov ntaub ntawv hlau (xws li carbon steel, stainless hlau, bronze, thiab lwm yam) tsis zoo li nws.Raws li qhov hnyav molecular ntawm polyethylene nce, cov khoom ua ntau hnav-resistant.

2. Kev ua haujlwm siab heev.Qhov cuam tshuam lub zog ntawm ultra-siab molecular hnyav polyethylene muaj feem xyuam rau nws qhov hnyav molecular.Thaum qhov hnyav molecular qis dua 2 lab, qhov cuam tshuam lub zog nce nrog qhov nce ntawm qhov hnyav molecular, thiab nce mus txog qhov siab tshaj ntawm 2 lab.Tom qab lub ncov, qhov cuam tshuam lub zog nce nrog qhov hnyav molecular.yuav poob.Qhov no yog vim hais tias cov saw molecular yog txawv txav thiab cuam tshuam nws cov photocrystallization, yog li ntawd muaj ib tug loj amorphous cheeb tsam nyob rau hauv lub macromolecule, uas yuav nqus tau ib tug loj cuam tshuam lub zog.

3. Tsawg kev sib txhuam coefficient.UHMWPE yog ib qho hnav-tiv taus, tsis tshua muaj coefficient ntawm kev sib txhuam thiab zoo nws tus kheej lubrication, thiab yog ib qho khoom siv zoo tagnrho rau cov kabmob bushings, sliders thiab linings.

Kev siv ultra-high molecular hnyav polyethylene raws li kev sib txhuam ntawm cov khoom siv tsis tau tsuas yog txhim kho lub neej hnav-tiv taus, tab sis kuj txuag lub zog.

4. Cov tshuaj tiv thaiv zoo.Ultra-siab molecular hnyav polyethylene muaj tshuaj zoo corrosion kuj.Tsuas yog cov concentrated nitric acid thiab concentrated sulfuric acid, nws yuav tsis raug corroded nyob rau hauv tag nrho cov lye thiab acid daws, thiab yuav siv tau nyob rau hauv concentrated hydrochloric acid ntawm qhov kub thiab txias (80 ° C, Nws tseem ruaj khov nyob rau hauv <20% nitric acid, < 75% sulfuric acid, thiab nws kuj tseem ruaj khov hauv dej, kua ntxhua.)

Txawm li cas los xij, ultra-high molecular hnyav polyethylene yog ib qho yooj yim heev rau o nyob rau hauv cov tshuaj tsw qab los yog halogenated tebchaw (tshwj xeeb tshaj yog nyob rau hauv lub kub kub), yog li tshwj xeeb yuav tsum tau them nyiaj tshwj xeeb thaum thov.

5. Kev nqus dej tsawg heev.UHMWPE muaj qhov nqus dej tsawg heev, nws yuav luag tsis nqus dej, tsis o hauv dej, thiab nqus dej tsawg dua li nylon.

6. Cov khoom cua sov.Raws li txoj kev ntawm ASTM (load 4.6kg / cm2), qhov kub thiab txias distortion yog 85 ℃.Nyob rau hauv ib tug me me load, qhov kev pab cuam kub yuav ncav cuag 90 ℃.Hauv cov xwm txheej tshwj xeeb, nws raug tso cai siv ntawm qhov kub siab dua.High molecular yuag polyethylene yog ib yam khoom uas zoo heev toughness, yog li nws tsis tshua muaj kuj kuj zoo heev, thiab nws tseem muaj ib tug tej yam degree ntawm ductility ntawm ib tug tsawg kub ntawm -269 ° C, thiab tsis muaj kos npe rau ntawm embrittlement.

7. Cov khoom siv hluav taws xob.UHMWPE muaj cov khoom siv hluav taws xob zoo heev hauv qhov kub thiab txias, nws qhov ntim tsis kam yog 10-18CM, nws qhov hluav taws xob tawg yog 50KV / hli, thiab nws qhov dielectric tas li yog 2.3.Nyob rau hauv qhov kub thiab qhov ntau zaus, nws cov khoom hluav taws xob hloov pauv tsawg heev.Nyob rau hauv lub tshav kub-resistant kub ntau yam, nws yog heev haum rau siv raws li structural ntaub ntawv nyob rau hauv hluav taws xob engineering thiab cov ntaub ntawv nyob rau hauv daim ntawv mills.

8. Non-toxic ultra-high molecular weight polyethylene yog tasteless, tsis muaj tshuaj lom, tsis muaj ntxhiab, tsis muaj corrosive, thiab muaj physiological ncig thiab physiological adaptability.Lub Chaw Tswj Xyuas Khoom Noj thiab Tshuaj Hauv Tebchaws Meskas (FDA) thiab Tebchaws Meskas Lub Tsev Haujlwm Saib Xyuas Kev Ua Liaj Ua Teb (USDA) tso cai rau nws siv rau kev sib cuag nrog zaub mov thiab tshuaj.

Nws cov yam ntxwv, tshwj xeeb tshaj yog hnav tsis kam, cuam tshuam tsis kam, thiab nws tus kheej lubricating zog, yog qhov zoo tshaj plaws ntawm engineering plastics.

Qhov loj me

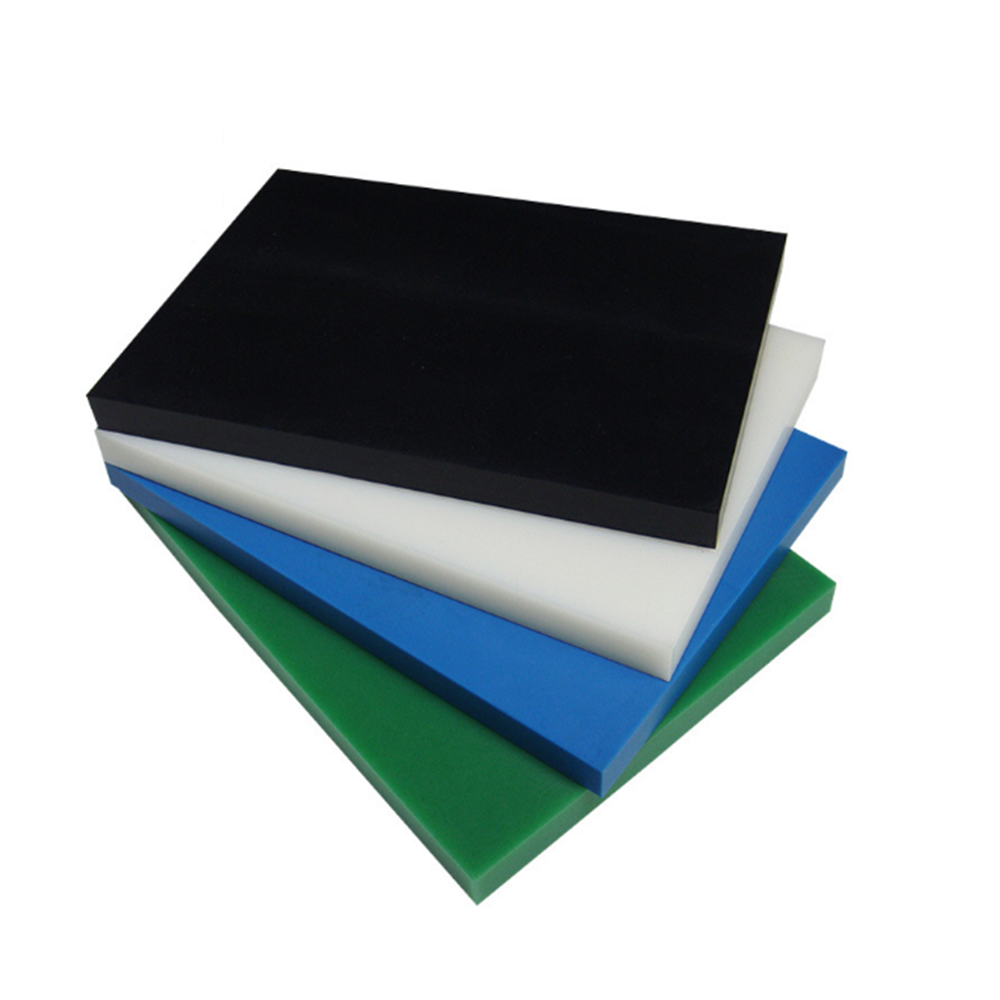

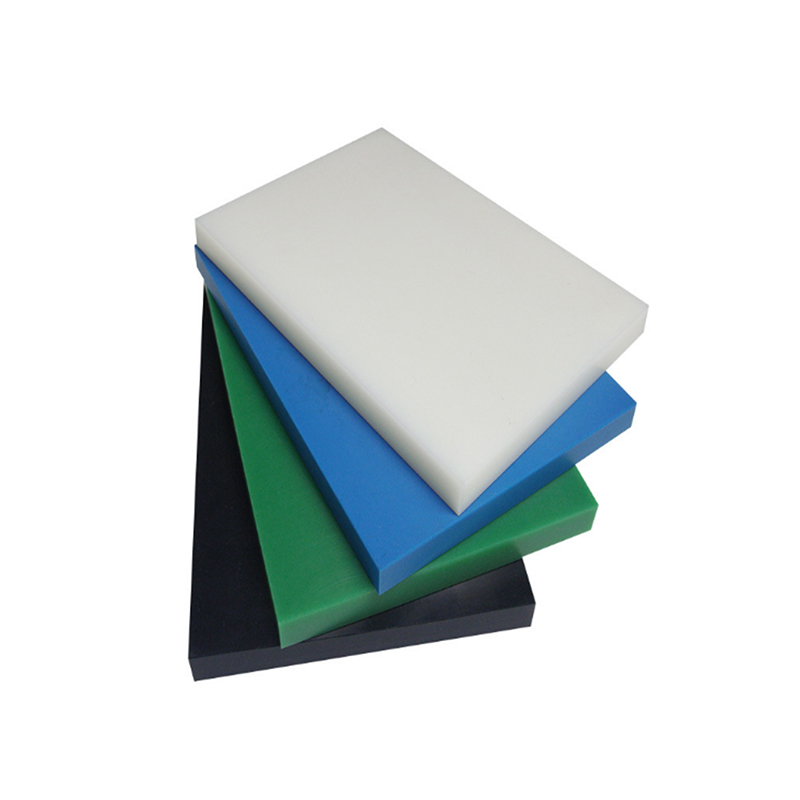

| Khoom npe | Txheej txheem ntau lawm | Loj (mm) | xim |

| UHMWPE Sheet | pwm nias | 2030 * 3030 * 10-200 hli | dawb, dub, xiav, ntsuab, thiab lwm yam |

| 1240 * 4040 * 10-200 hli | |||

| 1250 * 3050 * 10-200 hli | |||

| 2100 * 6100 * 10-200 hli | |||

| 2050 * 5050 * 10-200 hli | |||

| 1200 * 3000 * 10-200 hli | |||

| 1550 * 7050 * 10-200 hli |

Khoom siv

Ultra-high molecular hnyav polyethylene hais txog cov qauv linear polyethylene nrog ib qho hnyav molecular ntau dua 3 lab.Nws yog cov yas engineering nrog kev ua haujlwm zoo tshaj plaws.Nws tsib lub zog yog hnav tsis kam, cuam tshuam tsis kam, corrosion kuj, nws tus kheej lubrication, thiab cuam tshuam lub zog nqus.Muaj cov yas zoo tshaj plaws, paub thoob ntiaj teb li "cov ntaub ntawv zoo heev".

1. Daim ntawv thov raws li hnav tsis kam thiab cuam tshuam tsis kam

1) Textile machinery

Textile machinery yog thawj daim ntawv thov teb ntawm UHMWPE.Tam sim no, muaj qhov nruab nrab ntawm 30 UHMWPE qhov chaw siv txawv teb chaws hauv txhua lub tshuab textile, xws li shuttle picks, shuttle sticks, gears, couplings, sweeping rods, buffer blocks, eccentrics, rod bushings, swinging back beams, etc. hnav cov khoom.

2) Ntawv ua machinery

Daim ntawv tshuab yog qhov thib ob ntawm UHMWPE daim ntawv thov.Tam sim no, tus nqi ntawm UHMWPE siv hauv papermaking machinery suav txog 10% ntawm tag nrho.Qhia log, scrapers, lim, thiab lwm yam.

3) Ntim machinery

Siv UHMWPE los hloov kho cov fluoroplastics los ua cov lus qhia, cov rooj zaum slider, cov phaj ruaj khov, thiab lwm yam.

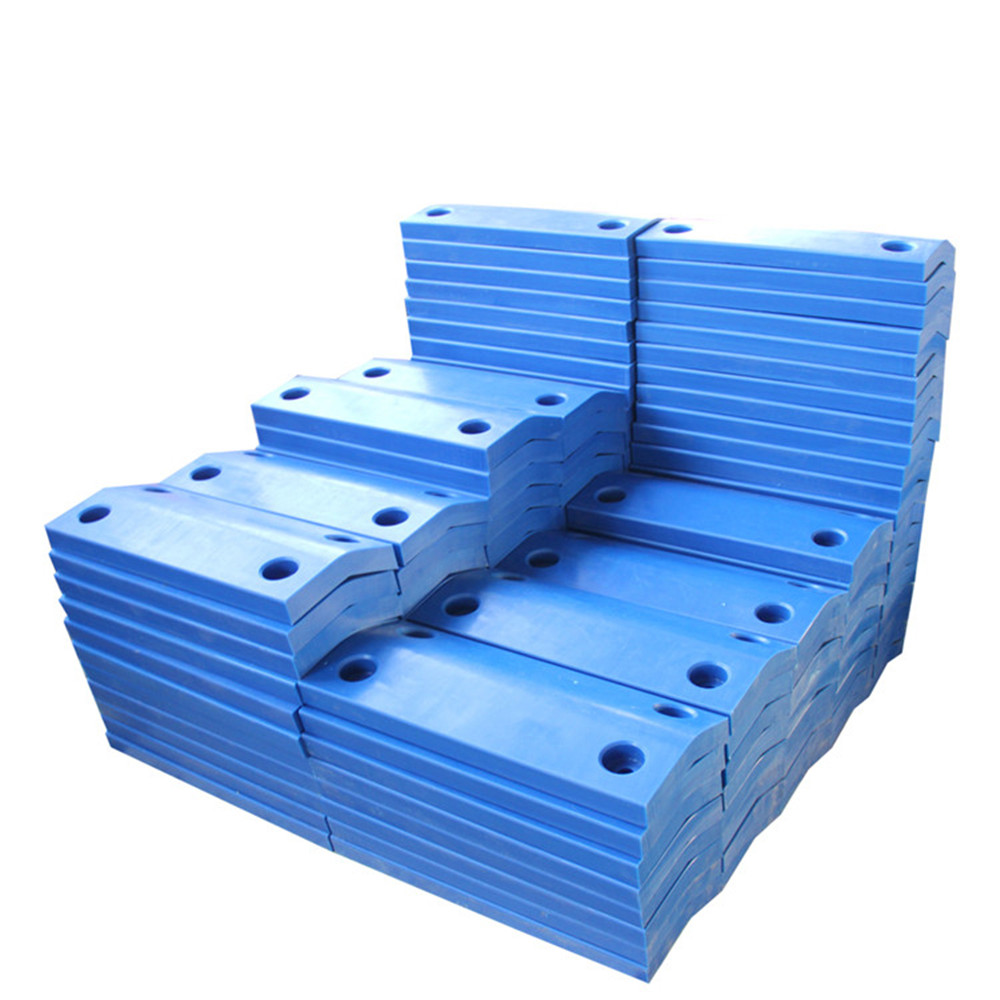

4) General machinery

UHMWPE tuaj yeem siv los ua cov iav, cams, impellers, rollers, pulleys, bearings, bushes, bushings, pins, gaskets, gaskets, elastic couplings, screws, yeeb nkab clamps, thiab lwm yam xws li kev tiv thaiv panels ntawm docks thiab choj piers.

2. Daim ntawv thov raws li nws tus kheej lubricating thiab tsis-stick zog

1) kev khaws cia thiab kev thauj mus los

UHMWPE tuaj yeem siv los ua cov hmoov txheej, xws li: silo, hopper, chute thiab lwm yam khoom siv rov qab, zawv zawg qhov chaw, chais, thiab lwm yam. Coal hopper, hmoov khoom hopper thiab lwm yam hopper lining cia rau hauv hopper lining board.

2) Kev ua liaj ua teb, kev tsim kho tshuab

UHMWPE tuaj yeem siv los ua daim hlau tiv thaiv kev hnav thiab cov hlua khi rau kev ua liaj ua teb.

3) ntawv sau

UHMWPE tuaj yeem siv los ua skating sled boards, sled boards, thiab lwm yam.

3. Cov ntawv thov raws li kev tiv thaiv corrosion thiab tsis yog dej nqus

1) lub thawv ntim khoom

Siv UHMW-PE los ua cov ntim dej sov rau cov khoom siv hnub ci hnub ci yog tam sim no ib qho ntawm feem ntau siv teb ntawm UHMWPE.

2) Cov khoom siv tshuaj lom neeg

Siv UHMW-PE los ua cov khoom lag luam chemical, xws li: sealing fillers, packing material, vacuum mold boxes, pump components, bearing bushes, gears, sealing joints, thiab lwm yam.

3) lub raj xa dej

4. Cov ntawv thov uas feem ntau yog tu cev thiab tsis muaj tshuaj lom

1) kev lag luam zaub mov thiab dej haus

Nyob rau hauv kev lag luam dej haus, nws zoo heev hnav tsis kam, cuam tshuam tsis kam, nws tus kheej-lubrication thiab non-toxicity yog tsuas yog siv los tsim ntau yam iav, cams, conveyor kab hnav-resistant guardrails, gaskets, qhia rails thiab ntau yam kev sib txhuam, nws tus kheej- lubricating Lubricated bushings, liners, thiab lwm yam xws li: guardrails, hnub qub log, coj gears, bearing bushes, thiab lwm yam. ntawm cov khoom noj machinery.

5.Application ntawm lwm yam khoom: nkoj qhov chaw, tsis tshua muaj kub mechanical qhov chaw, thiab lwm yam.

1) daim ntawv thov kub tsis kam

2) Kev siv hluav taws xob rwb thaiv tsev

3) Kev siv hauv cov mines

peb kuj tuaj yeem ua tau

UHMWPE + MoS2 daim ntawv

Impact-Resistant UHMWPE daim ntawv

Anti-static UHMWPE ntawv

Nplaim Retardant UHMWPE ntawv

Anti-Radiation UHMWPE daim ntawv

Anti-UV UHMWPE ntawv