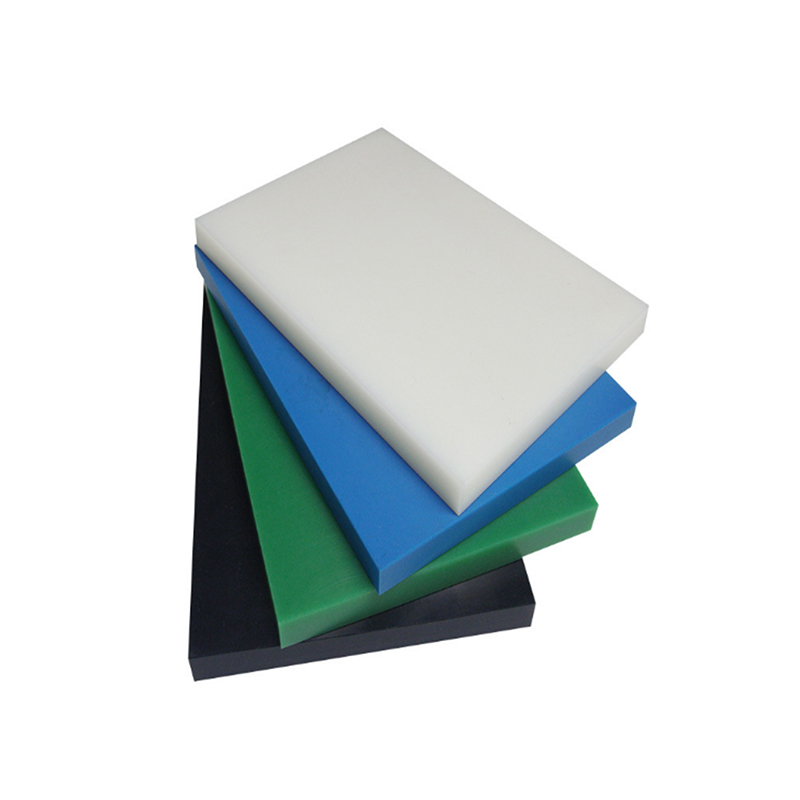

UHMWPE tub

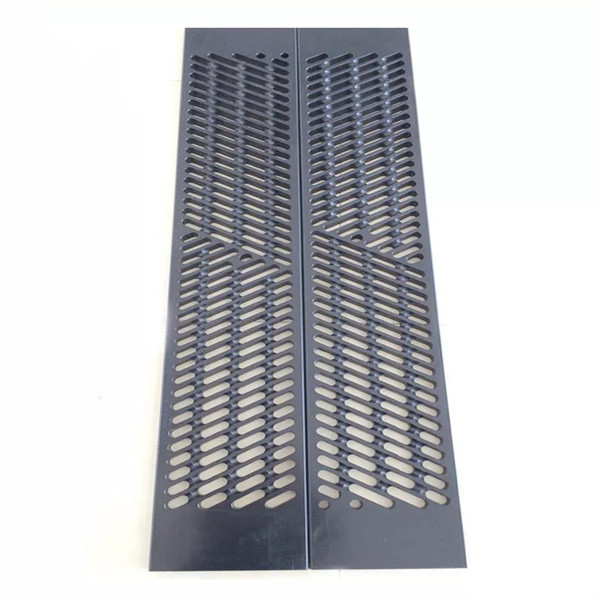

UHMWPE yeeb nkab:

Ultra-siab molecular hnyav polyethylene (UHIMW-PE) yeeb nkab yog ib hom tshiab ntawm cov yeeb nkab yas uas yog hnav-resistant, cuam tshuam-resistant, corrosion-resistant, tsis-absorbent thiab nws tus kheej-lubricating, yog li nws yog dav siv nyob rau hauv ntau yam teb:

1. Kev thauj mus los ntev ntawm cov roj: vim yog corrosion ntawm cov av acidic hnyav, dej hiav txwv thiab dej ntsev nyob ib ncig ntawm cov roj av, thiab kev cuam tshuam ntawm cov roj sulfur-muaj roj, kev pabcuam lub neej ntawm cov kav hlau steel feem ntau tsuas yog ob peb lub hlis. , thiab feem ntau ntawm cov roj crude yog cov viscosity siab, uas yooj yim rau kev thauj mus los thaum lub sij hawm thauj mus los.Kev tso dej, tshwj xeeb tshaj yog nyob rau lub caij ntuj no, cov kav dej yuav tsum tau nruab nrog lub tshuab cua sov thiab cov txheej txheem thermal rwb thaiv tsev, thiab nws tuaj yeem txhim kho kev sib kis tau zoo thiab kev pabcuam lub neej ntawm cov kav dej.

2. Grouting filling yeeb nkab: nto subence thiab tawg los ntawm underground mining yuav tsum tau tailings dej grouting filling, hauv av drilling, high-pressure grouting reinforcement, filling ntawm sib cais txheej qhov chaw, mitigation thiab kev tswj ntawm qhov chaw subcentric ceev, siv cov composite. yeeb nkab tuaj yeem txhim kho qhov kev xa tawm thiab kev lag luam zoo ntawm qhov project.

3. Kev lag luam tshuaj: kev thauj mus los ntawm cov xov xwm corrosive heev xws li muaj zog acid thiab alkali, kev thauj mus los ntawm brine, ntsev slurry thiab cov ntsev nyoos hauv kev lag luam ntsev.

4. Dredging tej yaam num: dredging tej yaam num xws li dej ntws, dej ntws, pas dej, chaw nres nkoj, docks thiab lwm yam dredging tej yaam num los thauj sediment.

5. Dej hiav txwv engineering: seawater thauj hauv seawater desalination.

6. Kev tsim vaj tsev hauv nroog: kev kho dej phwj tuaj, kev siv dej hauv tsev thiab kev xa hluav taws xob thiab hluav taws xob.

7. Ntau yam khoom siv kho tshuab: ultra-high molecular hnyav polyethylene (UHMW-PE) cov kav dej tuaj yeem ua tiav rau hauv cov kabmob bushes, zawv zawg bearings, bushings, rollers, gaskets, thiab lwm yam uas tsis yooj yim rau hnav, hloov cov khoom qub hlau, txo. cov nqi thiab txhim kho lub neej.

8. Grain conveying: huv si, tsis muaj tshuaj lom, siab ceev conveying, tsis thaiv, hnav-resistant, thiab nqi-zoo.Ultra-siab molecular hnyav polyethylene (UHMW-PE) yeeb nkab specifications thiab ua hauj lwm siab yuav ua tau raws li cov neeg siv yuav tsum tau.

UHMWPE roj zoo hauv ob sab phlu yeeb nkab yog cov khoom siv alloy raws li cov khoom siv siab molecular polymer, uas muaj kev hnav tsis zoo, kev cuam tshuam tsis kam, zoo ib puag ncig kev ntxhov siab tawg ua haujlwm, zoo rau nws tus kheej lubrication, tiv thaiv adhesion, tshuaj lom neeg ruaj khov thiab lwm yam khoom zoo.Cov tubing los tiv thaiv kev puas tsuaj nrog ultra-siab molecular hnyav polyethylene tuaj yeem txo qhov hnav ntawm tus pas nqus dej thiab cov phab ntsa sab hauv ntawm lub raj, txhim kho qhov hnav tsis kam ntawm lub raj thiab tus pas nrig thiab kev tiv thaiv corrosion hauv lub raj, zoo heev txo downhole tsis ua hauj lwm, thiab ncua lub twj tso kua mis tshuaj xyuas lub voj voog thiab tubing, Sucker pas nrig pab lub neej.

Txoj haujlwm ua haujlwm:

(1) UHMWPE roj zoo liner yog raws li lub hauv paus ntsiab lus ntawm sucker rod righting los xyuas kom meej tias tus pas nrig sucker yog cais los ntawm cov roj yeeb nkab yam tsis muaj kev sib cuag.Cov thev naus laus zis no feem ntau suav nrog: sucker rod nylon centralizer, sucker rod roller coupling thiab lwm yam.

(2) Lub ultra-siab molecular hnyav polyethylene roj zoo hauv ob sab phlu yeeb nkab ua kom zoo ib yam ntawm cov roj yeeb nkab thiab nqus pas nrig raws li txoj cai kev sib hloov.Cov tshuab no feem ntau suav nrog: rotating tubing thiab sucker pas nrig tshuab.Lub rotating wellhead yog ntsia thaum lub sij hawm ua hauj lwm, thiab thaum cov roj zoo nyob rau hauv ib txwm tsim, kev hloov ntawm kev sib cuag nto ntawm tus pas nrig thiab cov yeeb nkab yog guaranteed los ntawm rotating cov roj yeeb nkab hlua, li no prolonging lub neej kev pab cuam ntawm cov yeeb nkab pas nrig.

(3) Lub ultra-siab molecular hnyav polyethylene roj zoo hauv ob sab phlu yeeb nkab kom ntseeg tau tias cov roj yeeb nkab thiab cov pas nqus dej yog nyob rau hauv lub xeev ncab raws li txoj cai ncab, thiab txo cov eccentric hnav ntawm cov yeeb nkab pas nrig los ntawm kev nkag thiab tsis ruaj khov.Feem ntau muaj xws li: roj yeeb nkab anchoring tshuab, qis ib feem ntawm cov roj yeeb nkab luj tshuab thiab hydraulic tawm tswv yim twj roj twj siv tshuab.

(4) Los tiv thaiv hnav tshuab rau ultra-siab molecular hnyav polyethylene roj zoo liner.Kev tiv thaiv kev hnav khaub ncaws ntawm tus pas nrig yog tsim los ntawm kev hnav khaub ncaws polished, tiv thaiv hnav hauv nruab nrab lub tes tsho thiab tiv thaiv kev sib koom ua ke.Qhov saum npoo ntawm cov pas nrig los tiv thaiv yog hauv av thiab chrome-plated, thiab lub tes tsho tiv thaiv kev puas tsuaj yog lub tes tsho zoo nkauj nrog cov nylon reinforced 66. Vim yog cov txheej txheem rub txo ntawm cov pas nrig polished thiab lub tes tsho centralizing, kev sib txhuam. coefficient tsawg heev, yog li lub tes tsho centralizing yog tsau nyob rau hauv cov roj yeeb nkab, thiab cov anti-coj polished pas nrig slides nce thiab nqis nyob rau hauv lub anti-hnav centralizing lub tes tsho los xyuas kom meej tias lub sucker pas nrig hlua tsis tiv tauj cov roj yeeb nkab, yog li ntawd. kev sib txhuam thiab hnav ntawm tus pas nrig sucker thiab cov roj yeeb nkab tau hloov mus rau hauv kev sib txhuam thiab hnav los tiv thaiv kev hnav ntawm tus pas nqus dej nws tus kheej.Qhov qis hnav tsis kam ntawm tus pas nrig polished thiab lub tes tsho hauv nruab nrab ua rau hnav tsawg dua thiab ua tiav lub hom phiaj ntawm kev tiv thaiv eccentric hnav ntawm lub pas nrig raj.

Khoom nta:

1. Roj zoo liner muaj siab hnav tsis kam:

Qhov hnyav molecular ntawm ultra-high molecular hnyav polyethylene yeeb nkab yog siab li 2 lab los yog ntau tshaj, thiab qhov hnav index me me, uas ua rau nws muaj peev xwm tiv thaiv zawv zawg kev sib txhuam.Qhov hnav tsis kam yog 6.6 npaug siab dua li cov hlau zoo tib yam thiab 27.3 npaug ntawm cov hlau tsis muaj steel.Nws yog 17.9 npaug ntawm phenolic resin, 6 npaug ntawm nylon 6 thiab 4 npaug ntawm polyethylene, uas zoo heev txhim kho lub neej kev pab cuam ntawm cov kav dej.

2. UHMWPE roj zoo liner muaj kev cuam tshuam zoo:

Ntawm cov khoom siv hluav taws xob uas twb muaj lawm, qhov cuam tshuam qhov hnyav ntawm cov kav dej molecular hnyav yog qhov siab heev, thiab ntau cov ntaub ntawv yuav tawg, tawg, tawg lossis ntog kev nyuaj siab hauv qhov cuam tshuam ntawm kev tawg loj lossis rov ua dua.Raws li tus qauv GB1843, cov khoom no tau raug kuaj xyuas cov kab hluav taws xob cantilever kom ua tiav tsis muaj kev puas tsuaj, thiab tuaj yeem tiv taus qhov cuam tshuam sab nraud, sab hauv overload, thiab kev hloov pauv siab.

3. UHMWPE roj zoo liner muaj corrosion kuj:

UHMW-PE yog saturated molecular pawg qauv, yog li nws cov tshuaj lom neeg ruaj khov siab.Tsis corroded.Nws tuaj yeem siv rau hauv cov concentrated hydrochloric acid nrog cov concentration ntawm tsawg dua 80%, thiab yog qhov ruaj khov heev hauv sulfuric acid nrog cov concentration tsawg dua 75% thiab nitric acid nrog cov concentration tsawg dua 20%.

4. UHMWPE roj zoo liner muaj tus kheej lubrication zoo:

Vim tias cov yeeb nkab UHMWPE muaj cov khoom siv waxy, thiab nws tus kheej lubricating zoo heev.Kev sib txhuam coefficient (196N, 2 teev) tsuas yog 0.219MN / m (GB3960).Kev ua haujlwm ntawm tus kheej zawv zawg yog zoo dua li cov roj lubricated steel lossis tooj dag.Tshwj xeeb tshaj yog nyob rau hauv cov chaw uas hnyav ib puag ncig, plua plav thiab sediment, qhuav lubrication kev ua tau zoo ntawm cov khoom no yog ntau nthuav tawm.Tsis tsuas yog nws tuaj yeem txav tau yooj yim, tab sis kuj tseem tiv thaiv cov khoom ua haujlwm los ntawm kev hnav lossis lim.

5. UHMWPE roj zoo liner muaj qhov kub thiab txias tsis kam:

Lub ultra-high molecular hnyav polyethylene yeeb nkab muaj qhov kub thiab txias tsis kam, thiab nws cov kev cuam tshuam tsis kam thiab hnav tsis kam yog qhov hloov pauv ntawm rho tawm 269 degrees Celsius.Nws yog tam sim no tsuas yog engineering yas uas tuaj yeem ua haujlwm ntawm qhov kub thiab txias ze ze zero.Nyob rau tib lub sijhawm, ultra-high molecular hnyav polyethylene yeeb nkab muaj qhov dav ntawm qhov kub thiab txias thiab tuaj yeem ua haujlwm ntawm qhov kub ntawm -269 ° C txog 80 ° C rau lub sijhawm ntev.

6. UHMWPE roj zoo liner tsis yooj yim rau nplai:

Vim nws qhov kev sib txhuam me me thiab tsis muaj polarity, UHMWPE kav dej muaj qhov zoo ntawm qhov tsis zoo thiab cov yeeb nkab siab.Cov ntaub ntawv uas twb muaj lawm feem ntau teev nyob rau hauv nruab nrab nrog tus nqi pH ntawm 9 lossis ntau dua, tab sis cov yeeb nkab ultra-siab molecular hnyav polyethylene tsis ntsuas.Nws kuj tseem tsim nyog rau cov kav dej xws li roj av thiab av nkos.

7. UHMWPE roj zoo liner muaj lub neej ua haujlwm ntev:

UHMWPE cov kav dej muaj ob peb cov noob tsis txaus ntseeg hauv cov saw hlau molecular, qaug zog ua haujlwm ntau dua 500,000 zaug, ua haujlwm zoo rau ib puag ncig kev ntxhov siab tawg, tiv thaiv ib puag ncig kev ntxhov siab tawg> 4000h, ntau dua 2 npaug ntawm PE100, faus siv li ntawm 50 xyoo, tseem tuaj yeem tswj tau. ntau tshaj 70% ntawm cov khoom siv kho tshuab.

8. UHMWPE roj zoo liner yog ib qho yooj yim rau nruab:

Ultra-high molecular hnyav polyethylene pipeline (UHMW-PE) pipeline chav tsev yeeb nkab ntev tsuas yog ib feem yim ntawm qhov hnyav ntawm cov yeeb nkab steel, uas ua rau kev thauj khoom, tshem tawm, kev thauj mus los thiab kev teeb tsa yooj yim dua, thiab tuaj yeem txo qis kev siv zog ntawm cov neeg ua haujlwm.UHMW-PE pipeline yog anti-aging Muaj zog pw ua ke, tsis yooj yim rau hnub nyoog tom qab 50 xyoo.Nws tuaj yeem ntsia tau rau saum av lossis faus hauv av.Txawm hais tias nws yog welded los yog flanged thaum lub sij hawm installation, nws muaj kev ruaj ntseg, txhim khu kev qha, ceev thiab yooj yim, tsis muaj kev tiv thaiv corrosion, kev txuag hluav taws xob, thiab kev txuag hluav taws xob, uas qhia tag nrho cov "kev txuag hluav taws xob, kev tiv thaiv ib puag ncig, kev txuag hluav taws xob thiab kev txuag" zoo ntawm siv UHMWPE kav dej.

9. Lwm yam ntxwv ntawm UHMWPE roj zoo liner:

UHMWPE kav kuj muaj cov yam ntxwv zoo xws li lub zog nqus, nqus suab nrov, antistatic, tiv thaiv lub peev xwm rau electrons, tsis nqus dej, lub teeb tshwj xeeb lub ntiajteb txawj nqus, yooj yim machining, thiab xim.

Scope ntawm kev siv:

1. Cov roj ntau lawm qhov dej: Nws yog tsim rau cov roj qhov dej nrog ib feem hnav, waxing, corrosion hnyav, siab tsis ua hauj lwm tus nqi ntawm sucker rods thiab scaling ntawm cov kav roj.

2. Dej txhaj tshuaj zoo: haum rau cov dej txhaj tshuaj nrog hnyav corrosion thiab scaling.

3. Cov yeeb nkab xa khoom: Cov roj yeeb nkab qub uas muaj corrosion hnyav thiab ib nrab hnav uas tsis haum rau qhov downhole tuaj yeem siv los ua cov roj yeeb nkab tom qab hauv ob sab phlu.

4. Corrosive gas qhov dej: haum rau cov roj qhov dej corroded los ntawm H2S thiab CO2 gases.

5. Offshore roj qhov dej: Lub neej ntev tuaj yeem txo tus nqi ntawm cov roj offshore ntau lawm.